3 Ways To Model The Same Thing

If you haven’t noticed, people are different. They have different tastes in clothing, food, and music. You say tomato, I say ‘mater.

So it follows that designers will have different modeling methodologies. Sometimes, even circumstances or desired design intent dictate how you model something.

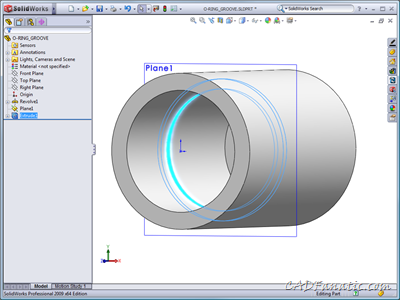

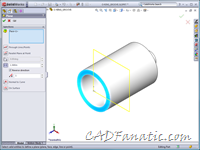

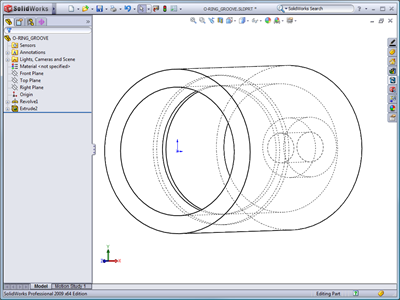

Take for instance this simple part with an o-ring groove in it:

I had a new SolidWorks user approach me a while back with the question, “How do I create something like this?”

I responded by showing them several different methods to achieve the same result.

One approach would be to do a Cut Revolve:

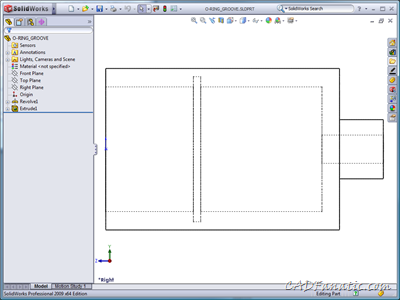

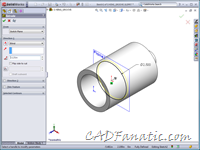

Another method (and what I believe a lot of folks would do) would be to offset a plane from the end and sketch the profile to cut:

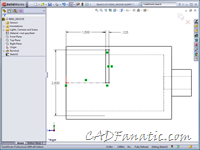

Then, simply do a Cut Extrusion:

I’m not really a fan of this method, unless your design intent requires the plane for something else (i.e., aligning the o-ring), as I try to have as clean a Feature Manager as possible. Sometimes, work geometry can clutter up things…

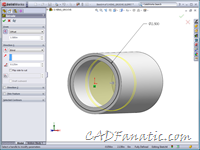

Another option, which is similar to the last yet may be unfamiliar to you, eliminates the creation of an offset work plane. You simply create the sketch on the existing end face and then do a Cut Extrude, offsetting the start of the cut.

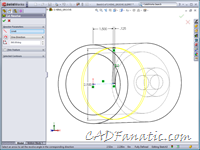

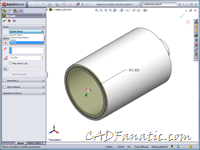

All of the above methods yield the same result, albeit with varying features and number of features:

Of course, there are multiple other ways that this could be accomplished, perhaps some better than these. The o-ring groove could even have simply been modeled in the original sketch, although that may not be considered a “best practice” by some…

All of this is to say that there isn’t really a right and wrong way to model. But sometimes one method is better than the other – and that is your call to make.

(Download SolidWorks 2009 file here.)

Pingback: 3 Ways To Model The Same Thing, by Brian McElyea()